Why Protective Packaging Matters in Modern Logistics

In today’s competitive B2B landscape, inadequate protective packaging accounts for up to 20% of product returns in e-commerce and wholesale operations. Choosing the right air cushion packaging affects shipping costs, storage efficiency, and sustainability commitments while reducing material costs by 30-40%.

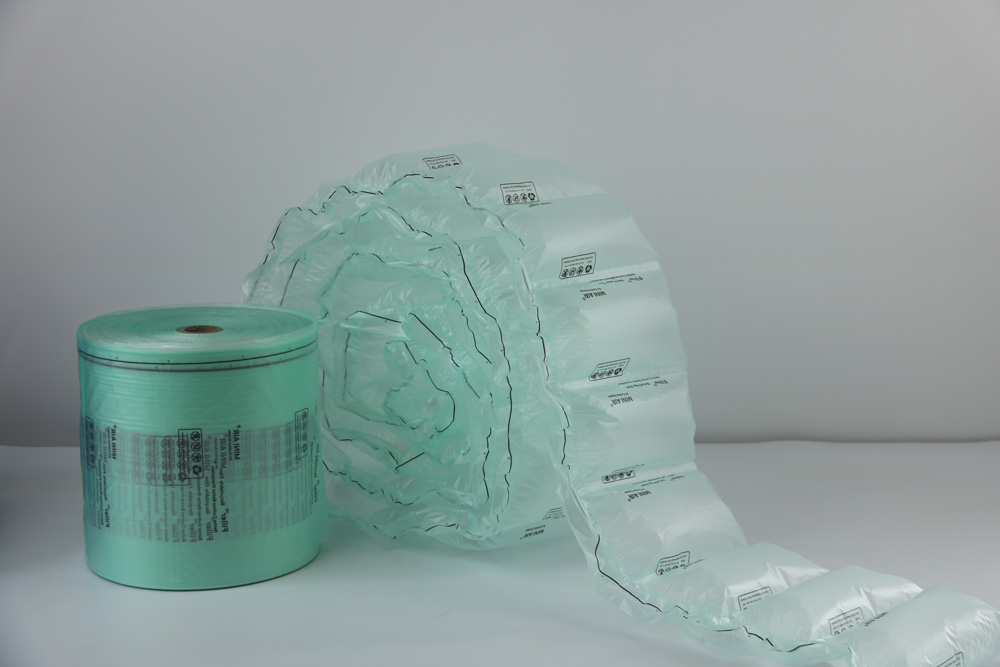

Air cushion packaging uses trapped air to absorb shock and prevent damage during shipping. These solutions inflate on-demand, offering significant storage and logistics advantages over rigid materials.

Understanding Air Cushion Packaging Types

Air Pillow Film consists of interconnected air-filled chambers that excel in void filling applications. These pillows conform to irregular spaces, preventing product movement inside boxes while occupying minimal storage space before inflation.

Air Bubble Film features evenly distributed air bubbles trapped between plastic layers, providing excellent surface protection against scratches and minor impacts. Available in various bubble sizes, this versatile material wraps individual items for 360-degree protection.

Air Column Bag utilizes vertical air columns that provide superior cushioning for fragile items. The column structure redistributes air upon impact, offering enhanced shock absorption and maintaining protective properties under repeated stress.

Material Selection Guide

Each air cushion packaging type is available in multiple material compositions offering distinct performance characteristics.

HDPE: Standard Performance Material

High-Density Polyethylene (HDPE) serves as the industry standard, offering reliable protection at competitive prices. It provides good puncture resistance and air retention for standard transit durations, making it ideal for cost-conscious operations and high-volume applications.

LDPE: Flexible Performance Option

Low-Density Polyethylene (LDPE) offers greater flexibility and conformability than HDPE. This softer material adapts readily to product contours and demonstrates excellent clarity, making it ideal for irregularly shaped items and applications where product visibility matters.

MAX: Next-Generation Protection Technology

MAX represents innovative material engineering that delivers superior performance through a thinner profile that reduces material consumption while maintaining protection standards. This advanced composition offers enhanced pressure resistance, superior air retention throughout extended shipping cycles, and improved durability against punctures and tears. The thinner profile provides significant operational advantages—businesses can store more packaging material in less space while the enhanced durability reduces packaging failures and damage claims. MAX is ideal for high-value shipments, international logistics, and operations prioritizing sustainability through material reduction.

Anti-Static: Specialized Electronic Protection

Anti-Static materials incorporate additives that prevent electrostatic discharge, providing dual protection—physical cushioning combined with electrical safety. Essential for computer components, semiconductors, printed circuit boards, and precision instruments sensitive to static electricity.

Recycled: Sustainable Packaging Solution

Recycled materials incorporate post-consumer or post-industrial plastic content, reducing environmental impact while maintaining protective performance. Many businesses now require suppliers to meet sustainability standards, making recycled packaging a competitive necessity for companies with environmental commitments.

Key Factors in Selection

Product Fragility: Match packaging type to fragility level—Air Column Bags for highly fragile items, Air Bubble Film for surface protection, Air Pillow Film for void filling. Material selection amplifies protection: MAX provides superior cushioning for fragile products, while HDPE suits robust items. Anti-Static becomes mandatory for sensitive electronics.

Shipping Distance and Handling: International shipments typically experience 3-5 transfer points. MAX material’s enhanced air retention maintains cushioning throughout multi-week transit periods, while standard HDPE or LDPE works well for local deliveries with minimal handling.

Cost-Efficiency: Calculate total cost of ownership. While MAX costs more per unit, its thinner profile reduces material consumption by 20-30%. On-demand inflation reduces storage costs by up to 95% compared to pre-inflated materials.

Environmental Impact: Recycled materials demonstrate environmental commitment, while MAX material’s thinner profile reduces plastic consumption. Consider end-of-life disposal—easily recyclable materials improve your environmental profile throughout the supply chain.

Operational Efficiency: Uninflated air cushion materials occupy minimal space, with MAX providing additional savings. Air Pillow Film systems with automated inflation increase packing speed, while Air Bubble Film offers flexibility for manual operations.

Matching Products and Materials to Use Cases

E-commerce Fulfillment: Air Pillow Film with HDPE or Recycled material for high-volume operations. Switch to MAX material for fragile or premium products.

Electronics Shipping: Air Column Bag with Anti-Static material for sensitive components. Air Bubble Film with Anti-Static provides cost-effective protection for less sensitive electronics.

International Logistics: Air Column Bag with MAX material for maximum protection during extended transit. Enhanced air retention and durability justify the premium cost.

Sustainable Packaging Programs: Any packaging type with Recycled or MAX material. Recycled materials support sustainability goals, while MAX reduces total plastic consumption.

Premium Product Protection: Air Column Bag with MAX material delivers the highest protection level with professional appearance aligning with premium positioning.

Best Practices for Implementation

Test and Analyze: Establish baseline damage rates with current materials over 60-90 days. Order sample quantities of different material compositions and conduct controlled testing to multiple destinations. Compare damage rates, material performance, and cost per shipment to identify optimal combinations.

Optimize by Product Category: Create a material matrix matching packaging types and materials to product categories. High-value fragile items warrant MAX material investment, while routine shipments perform well with standard HDPE. Document these decisions to ensure consistent application across packing operations.

Monitor and Improve: Continuously track damage rates by material type, material costs per shipment, packing time, and customer feedback. Review metrics quarterly to identify optimization opportunities as your product mix evolves.

Making the Right Choice for Your Business

Selecting optimal air cushion packaging requires matching the right product type with appropriate material composition. Air Pillow Film, Air Bubble Film, and Air Column Bag each serve distinct protective functions, while material options—HDPE, LDPE, MAX, Anti-Static, and Recycled—provide performance and cost flexibility.

Most successful B2B operations use multiple combinations, matching specific solutions to product requirements rather than one-size-fits-all approaches. Start by categorizing your products by fragility level and shipping profile, then map appropriate air cushion packaging types and materials to each category.

When sourcing air cushion packaging solutions, partnering with an experienced protective packaging supplier ensures access to quality materials and expert guidance. Ameson specializes in providing comprehensive air cushion packaging solutions, offering the full range of product types and material options discussed in this guide, including innovative materials like MAX that deliver superior performance for demanding applications.

The investment in proper protective packaging pays dividends through reduced damage claims, lower return rates, improved customer satisfaction, and enhanced operational efficiency. As e-commerce and B2B logistics continue growing, businesses that prioritize strategic packaging decisions will maintain competitive advantages in cost management and customer experience.